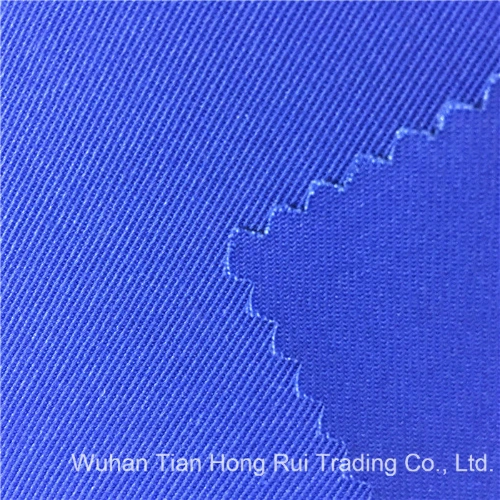

100% Cotton Twill Fabric with Fr Treatment for Fireman, Oil & Petroal Industry

Flame Retardant Fabric Twill Cotton flame retardant fabric is on the basis of cotton dyed fabric treated with flame reta;

Basic Info

| Model NO. | THR003Y |

| Yarn Type | Combed |

| Width | 58/59" |

| Tarn Count | 16*10 |

| Color | for Your Choose |

| Tear Strength | >400n |

| Color Fastness Dry Cleaning | 3-4 |

| Color Fastness for Washing | 4 |

| Feature | Flame Retardant, Shrink-Resistant |

| Use | Garment, Industry, Suit, Ect. |

| Finish | Fr(50-100times Washing) |

| Sample | Available for You |

| Certificate | En11611 |

| Transport Package | Poly Bag |

| Specification | 100% Cotton |

| Trademark | THR |

| Origin | Wuhan, China |

| Production Capacity | 500000 Meter/Month |

Product Description

Flame Retardant Fabric TwillCotton flame retardant fabric is on the basis of cotton dyed fabric treated with flame retardant process. It contains flame retardant cotton plain cloth, flame retardant cotton yarn card, flame retardant cotton satin drill and flame retardant cotton canvas.There are three kinds of treatment methods. CP, PROBAN, PYROAVTEX.Nowsays, CP and PROBAN are the most popular methods in the globe.

| Fabric content | 100%cotton | Style | 3/1 Twill |

| Fabric weight | 220GSM | Fabric width | 57/58", 150cm |

| ProductIntroduction | FRCOTTON Series textile, is one line of FR Series forIndustrial workwear which is in pure cotton.Excellent advantages1. Permanent flame retardant performance2. Excellent shrinkage under industry washing cycles3. Pure cotton, ECO-friendly Okeo Tex-1004. Comfortable to wear, no smell5. Heavy item FRCOTTON 220AS suitable for welder workwearApplicationIt is specialized used for professional welders clothing in different areas such as Machinery, Metallurgy, Oil and Gas Pipeline construction, Automotive etc.StandardEN 11611(EN470-1) -weldingEN 11612(EN531) -industrial flame and heat hazardsEN14116(EN 533) index 3- heat and flame retardantNFPA2112ASTMF11506 | ||

Flame Retardant Fabric Test

EN11611(EN470-1): The latest European standard welding standard, take the place of EN470 standard.

EN11612(EN531): Under the environment of high temperature, operation workers flame retardant protective clothing standard.

EN14116(EN533): Tooling protective clothing - related fabrics and composite - insulation, or - short spreading combustion performance testing.

Feature

Due to the Permanent flame retardancy, Cotton flame retardant fabric have broadly application prospect. It is understood that the scope of application of cotton flame retardant fabric is very wide, in addition to industrial textiles, building decoration, interior decoration and other traffic tools play an irreplaceable role in the field of protective clothing, also played a role of flame retardant protective clothing,flame retardant fabric clothes have excellent washing performance, non-toxic to human body. Safe and reliable, breathable, soft, comfortable to wear.

Industry Use

Products are widely used in Petroleum and Chemical, Metallurgical, Coal, Forestry, Traffic, Civil, Defense and other industries.

FR Cotton Series

Cotton Flame Retardant Twil FabricCotton Flame Retardant Sateen FabricCotton Flame Retardant Plain FabricCotton Flame Retardant Canvas FabricCotton Flame Retardant Denim Fabric

Color Disc

Our Main Products

. Flame Retardant Fabric . Acid-Alkali Resistant Fabric . Anti-Static Fabric. Oil and Water Repellent and soil release Fabric . Anti-UV Fabric. Anti-Bacteria & Anti-Odor Finishing Fabric. Multifunctional Flame Retardant Fabric. Flame Retardant Clothing and Workwear

Why choose Wuhan Tian Hong Rui?

. Efficient Delivery Sampling time: 5 workdays. Lead time: 15 workdays(no limits in meters). . Shipping Port Shanghai, Shenzhen, Ningbo, Wuhan. . Sample Free samples are available for your requirement. Generally speacking, customer charge the sample shipment at first, we will refund it back once formal order.. Good Quality Strict Quality Control before fabric dyeing. After the bulk production, the fabric will be inspected and inspection report will be issued. QC will inspect fabric 20% to 30% of total bulk as the third party again. We enjoy good reputation in European market.. Quick Response We will answer immediately or within 24 hours.

Order Process

Customer → Inquiry → Quotation → Agreement → Sample → Order Confirmed → Deposit Payment → Lab DIP → Bulk Production → Balance Payment →Shipping → Feedback

You may also like

Send inquiry

Send now